Skip to content

PROJECT MANAGEMENT

SGT’s ability to leverage a staff of seasoned

professionals who are dedicated to Your success – Your way – distinguishes SGT

from others.

- Recognized World-Record Project Performance Proven Program and Processes

- Adaptable Procedures to meet Site Specific Requirements Integrated Project Schedule

- Collaborative Approach Certainty of Results

- Safety Quality Cost Schedule

ENGINEERING

Qualified

Team + Field Experience + Proven Process = Project Success

Fully Integrated Design Engineering Team

- Integrated with Customer Engineering Team

- Integrated with Sub-Contractors

- Integrated with Construction Team

On-site Design Engineering Team during implementation

- Ensure design is installed to the requirements

- Quick response for field changes

Experienced Engineering Change Package Writers

- Have developed and reviewed ECPs for ~50% of PWR Power Plant

Highly Qualified Personnel

- Site programs and procedures

- EPRI ACAD Orientation

- EPRI ACAD Engineering Fundamentals

- EPRI ACAD Systems Engineering

Innovative, First-Of-A-Kind Designs

ENGINEERING COMPETENCIES

Civil /

Structural

- Layout and Building Design

- Containment Analysis and Design

- Concrete and Steel Design

- Seismic Analysis

- Dynamic Loading

- SQUG Qualifications

Mechanical / Piping

- Safety System Design and Evaluation

- Pipe Stress and Support Design

- Instrumentation Modifications

- Insulation Replacement and Modification

- Major Component Support Evaluation and Design

Electrical / I&C

- Evaluation of Changes to Plant

- Replacement Part Qualification

- Repairs to Existing Hardware

- Temporary Power Design and Evaluation / tea

- Fire Protection / NFPA 805

- Cybersecurity and Security

- Safeguards

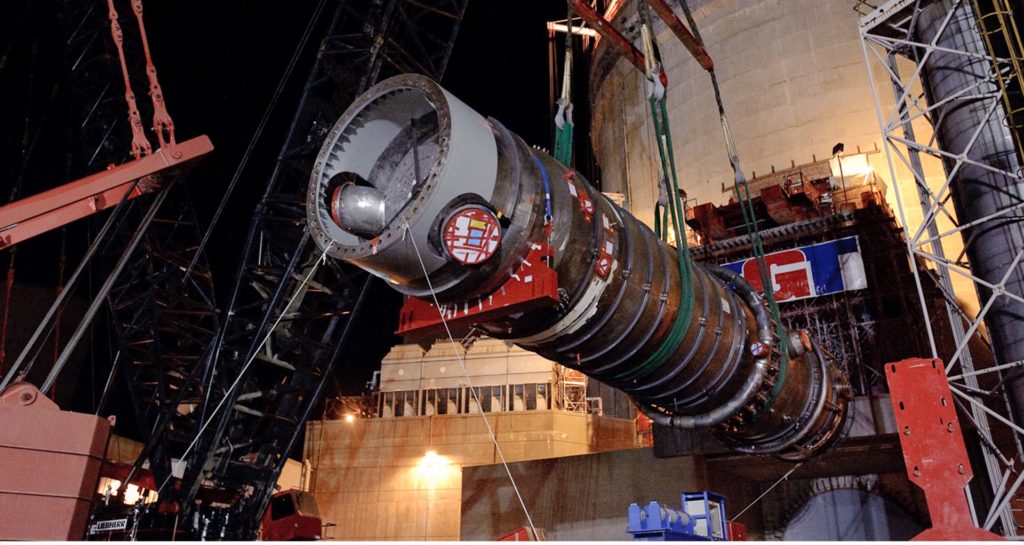

Rigging and Handling

- Soil Mechanics and Foundations

- Rigging Evaluations

- Load Path Evaluations

- Load Tests

Licensing

/ Permitting

- NRC Documentation Support

- 50.59 Screenings

- Local / State / Federal Permitting Support

Metrology

- Fit-Up Measurements

- Interference Evaluations

- As-Built Verifications

PROCUREMENT

Qualified

Team + Field Experience + Proven Process = Project Success

- Nuclear Safety to Commercial Materials

- Equipment and Components

- Commercial Grade Dedication Process

- Quality Receipt Inspection Process

- Warehouse Management

- Maintain an SGT Approved Suppliers List with optional use of

ASLs from parent companies and customers

CONSTRUCTION

Construction

Management

- Proven Construction Management capabilities with processes tailored to Safety Related and Non-Safety Related projects

- Integrated engineering and construction processes

- Continuous improvement and learning culture

- Rigorous Readiness Review process

- Schedule driven, cost focused

Building

Trades and Open Shop Experience

- Signatory to

the building trades’ “General Presidents Project Maintenance Agreement” (“GPPMA”).

- Membership on the GPPMA Executive Committee

Robust Communications Plan

- Plan of the Day (POD) Meetings

- Daily shift schedule status

- Performance Metrics tailored to project / customer needs

- Weekly Project Management Team Meetings

Task

Management Approach (major projects)

- Provides additional management oversight from planning/engineering

through execution phase

Field Engineering

- Continuous integration of design and technical requirements

- Early deployment to field

Proven

Work Control Process

- Adaptable to project / customer needs

- Design Engineering reviews ensure compliance with technical requirements

- Timely field change process supports execution

CONSTRUCTION COMPETENCIES

Civil

/ Structural

- Containment Openings

- Structural Steel

- Temporary Facilities and Permanent

- Building Installation

- Scaffolding / Work Platforms

- Coatings

Mechanical / Piping

- Diesel Generator Installation

- HVAC

- Fire Protection

- Temporary and Permanent Plant Supports

Electrical

/ I&C

- Electrical System and Component

- Repair, Replacement and Upgrades

- Controls Upgrades

- Temporary Power Design and Installation

- Security Systems

Rigging and Handling

- Non-Standard Components

- Haul Route Preparations

- Crane Installation and Modifications

- Customized Rigging Equipment

Welding

- RCS / Primary Piping

- Secondary Piping

- Instrumentation and Small Bore Piping

- Steel Containment Vessel Liner Plate

- Structural Steel

Metrology

- Fit-Up Measurements

- Interference Evaluations

- As-Built Verifications